Rollwasch® italiana spa

Robotic Finishing Tech

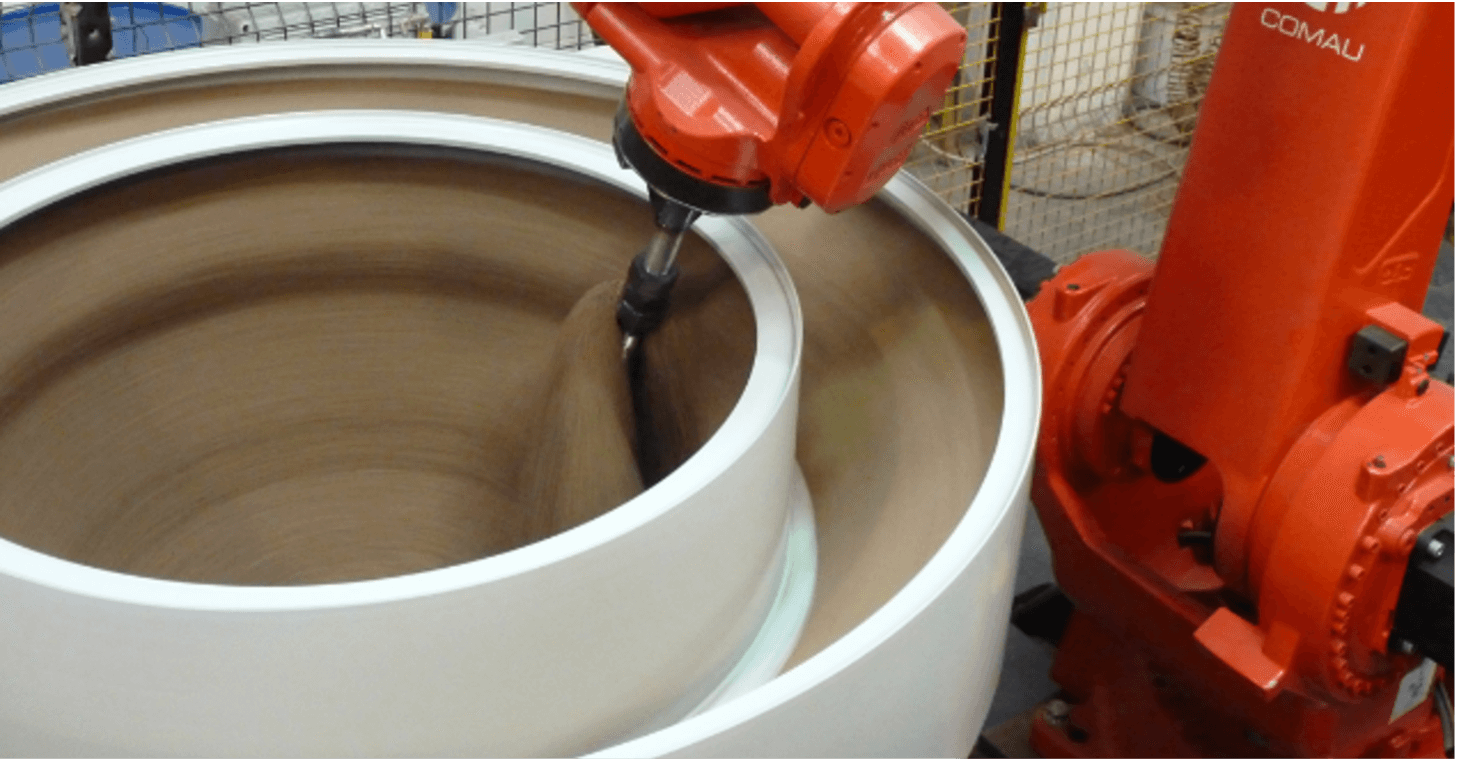

Rollwasch®’s machines and automatic systems programme for Wave Finishing “RoboTEP” allows to achieve new goals in the finishing standards, relying on the principles of centrifugal force. While with drag finishing you get results in hours or fractions, with Wave Finishing it only takes a few minutes.

This programme also offers combined solutions with robots (RoboTEP), matched with devices for the automatic replacement of media (Media Smart) and other exclusive innovations.

01

Wave Finishing

Combination of a static or dynamic exposure of a target to a media

02

Robotic Grinding

Identifying the wide experience in the grinding technology of Rollwasch®

03

Robotic Blasting

Identifying the growing experience in the blasting technology of Rollwasch®

04

Robotic HPW

Identifying the growing experience in the HPW (High Pressure Washing) technology of Rollwasch®

05

Vibrobotic

Identifying the wide experience in the vibratory finishing technology of Rollwasch®

06

Acti Sync Tech

Identifying the wide experience in the vibratory finishing technology of Rollwasch®

Wave Finishing

The term “Wave Finishing” has been given to the combination of a static or dynamic (i.e.: rotary) exposure of a target workpiece to a media which is rotating to a certain centrifugal force, in a wide rotary bowl. The target is submerged into the media, with a certain angle and depth, thus acting an extremely efficient surface finishing, completely supported by a robot of a suitable type and a software with “N” recipes is available for the best finishing result.

The extension “Multi Channel” or “MCH” (patented) is given to the same as above, but where the exposition of the target can be in one of the concentric channels number 1, 2, 3 or N, where in every channel the finishing media could be different and with increasing or decreasing material removal rate, depending on the finishing task requirements.

Rollwasch® is today the only Company in the world able to provide this smart finishing principle, applying it to any size or kind of system, depending on the final needs.

The Option to finish a component with a Wave Finishing MCH system is a rather good solution when components are typically: Hard Metal Tools, Aerospace blades, vanes and bladed disks, complex mechanical components, forged parts in the final step after machining, precision machined components, Automotive parts like injectors or similar, medical parts.

Nevertheless, Wave Finishing MCH is the perfect solution for much many other apps, where final surface rugosity must be reduced as much as possible.

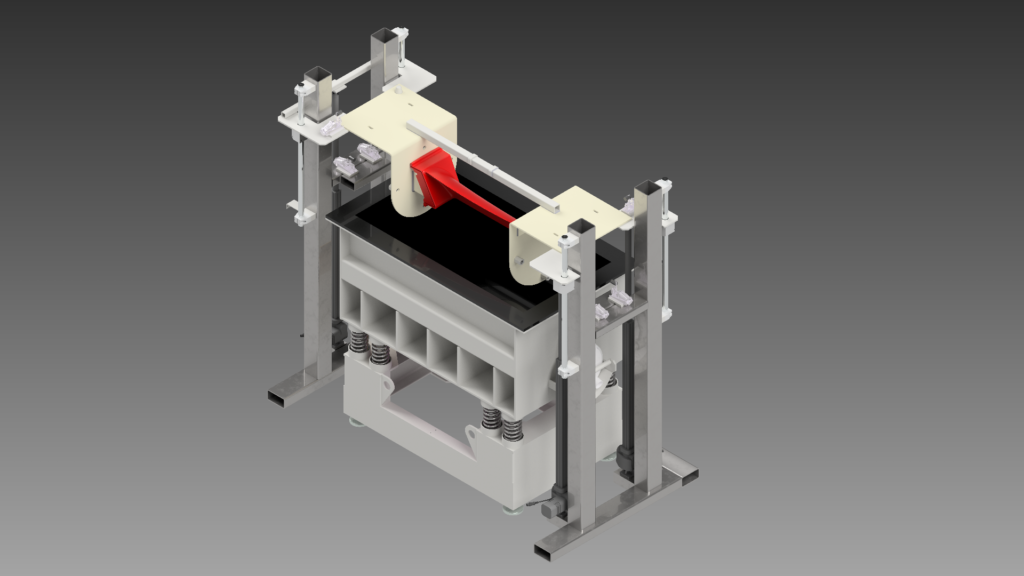

Robotic Grinding

Our finishing systems are almost based on grinding belt, mounted over two contact-wheels, nevertheless we can offer also solutions based on grinding wheels and special abrasives solutions – including grinding belts specifically designed for plastic components.

Many items prepared with robotic grinding can be further finished or superfinished with further steps like Wave Finishing, or Microfluid technology or other similar apps where surface roughness, left from the finest grinding belt, becomes much more reduced and refined, with automatic and eco-sustainable processes.

Robotic Blasting

Our finishing systems are open to multidisciplinary design, offering important advantages.

Many items prepared with robotic blasting can be further finished or superfinished with further steps like Wave Finishing, or Microfluid technology or even coating.

Robotic HPW

Our finishing systems are almost open to multidisciplinary design, offering important advantages.

Many items prepared with Robotic-HPW, can be further finished or superfinished with further steps like coating or top-coating.

Vibrobotic

Our finishing systems are based on solutions to allow the robot to reach a “clean area” out of the finishing media, thanks to several special devices applied to our vibratory finishing machines.

Many items prepared with the “VibROBOTIC” systems can be further finished or superfinished with further steps like Wave Finishing, or Microfluid technology or final Coating.

Acti Sync Tech

Our finishing systems are based on solutions to allow the robot to reach a “clean area” out of the finishing media, thanks to several special devices applied to our vibratory finishing machines.

Many items prepared with the “Acti Sync Tech” systems can be further finished or superfinished with further steps like Wave Finishing, or Microfluid technology or final Coating.

5 Specific Patented Solutions

Multidisciplinary Technology